Summary

I am Muhammad Kamran Khan, I have done B.Sc. Chemical engineering technology and also done IOSH managing safely and Nebosh IGC from International HSE Council LLC attend classes certificate.

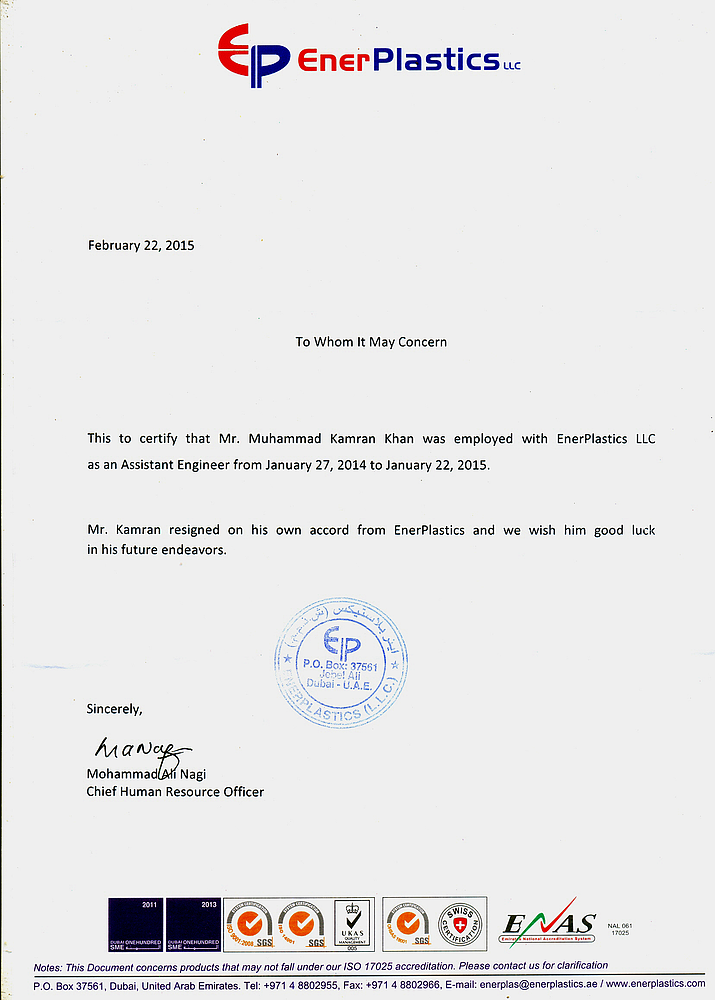

I have total 3-4 year work experience, one year experience from Ener-Plast LLC Jabali-Ali ,two year work experience in oil and sector with OGDCL and internships in PAK American fertilizer (Agree Tech) and Olympia Chemical Limited and Oil and Gas Development Company.

Projects

Experience

Drilling Fluids Engineer

Worked on project base oil and gas development company. (April 2015 to April 2017)

RESPONSIBILITIES

•Monitor and control all HSE matters related with project team members and contractors in ensuring that the

Project is in compliance with the project requirement

•Responsible for the health, safety, environment, security & emergency throughout the project duration to achieve safe

project completion.

•Ensure that Project is executed in compliance with HSE Management Plan, HSE Management Procedure, Environmental Management Procedure, Potential Risk Register, Potential Risk Mitigation Plan, HSE Audit Plan/Procedure and any other HSE related documents.

•Monitor and update the HSE risks register and ensure all mitigation plans are strictly adhere to throughout the project execution.

•Having experience to provide inputs in HSE related deliverables such as HSE Management Plan, HSE Management Procedure, Environmental Management Procedure, Potential Risk Register, and Potential Risk Mitigation Plan.

•Having experience to review and participate in development of HSE management system.

•Having experience to prepare HSE training program and conduct training as supervisor.

•Proficient in Microsoft Office applications i.e. Word, Excel, PowerPoint and Project.

•Good written and spoken communication skills in English and able to work with all levels of management and multinational staff.

•Supervise the running of drilling fluid, mixing, pumping and chemical treatment.

•Prepare an optimum solution of drilling fluid according to the requirement of drilling phases.

• Checking & maintaining mud properties filing out various daily reports.

• Ensuring safety & HSE in drilling fluids related areas on site.

•Assist cement department in cementation job.

• Developing & communicating rig specific fluids management plans, work safely and insure that all safety standards

are met and maintained.

Production Engineer

Reporting To Production & Plant Manager

Develop best practices to improve production capacity, quality and reliability.

Lead as a shift engineer, where I was involved in process, maintenance, designing, erection and commissioning.

Troubleshooting day- to- day problems of process plant machinery.

Maintenance of different Equipment like: Twin Screw Extruder, Heat Exchanger, Compressor, Chillers, Pumps, Injection Moulding Machines.

Preparation & implementation of Preventive Maintenance schedules for smooth & efficient operation of plant machinery.

Ensure that mechanical activities are safe, efficient and according to mentioned standards.

Design & route selection of piping according to process requirements.

Writing Standard operating procedures (SOP's) for machines